Sign up for Flow Kiosk

Already have an account? Sign in now

By registering you are agreeing to our

Terms of Service

Loading Flow

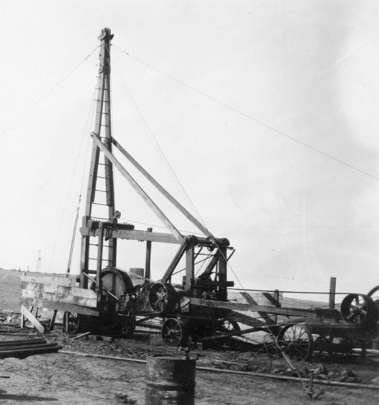

SPUDDING & DRILLING RIGS

B2

SPUDDERS:

Spudders, also called cable-tool rigs or ballistic well drilling rigs, were the preliminary drilling rigs in the field. They raised and dropped a drill string with a heavy carbide tipped drill bit that chiseled through the rock by finely pulverizing the subsurface materials. The drill string was composed of the upper drill rods, a set of “jars” (interlocking “sliders” that help transmit additional energy to the drill bit and assist in removing the bit if it got stuck) and the drill bit. During the drilling process, the drill string was periodically removed from the borehole and a bailer lowered to collect the drill cuttings (rock fragments, soil, etc.). The bailer was a bucket-like tool with a trapdoor in the base. If the borehole was dry, water was added so that the drill cuttings would flow into the bailer. When lifted, the trapdoor closed and the cuttings were then raised and removed. Since the drill string must be raised and lowered to advance the boring, the casing (larger diameter outer piping) was typically used to hold back upper soil materials and to stabilize the borehole.

Spudders are simpler and cheaper than similarly sized rotary rigs, and loud and very slow to operate. A cable-tool rig can drill 25 feet to 60 feet of hard rock a day, where a newer rotary drill cat-top-head rig equipped with a down- the-hole hammer can drill 500 feet or more per day, depending on size and formation hardness. Spudders are nearly obsolete today, because of the slow nature (and expense) of the time-consuming drilling process.